1. UV Stabilisation of Nonwovens

Ultraviolet light (UV) is a natural part of sunlight. When objects get exposed to UV light for extended periods, they start to degrade. Nonwovens are no exception.

“UV protection of nonwovens is popular in agriculture. Heavy exposure to sunlight can make nonwovens brittle and more prone to fading and tearing. Yet, with UV stabilisation, fabrics last for two years in garden beds in good condition,“ explains Milan Polouček from Milmar.

So, how to achieve UV stability? Adding UV stabilisers to the polypropylene granulate during production does the job.

TIP: Here’s how large-scale producers use UV-stable nonwovens to grow strawberries.

2. Antistatic Nonwovens

Widely used in electronics, optics and other clean manufacturing — as dust can easily damage delicate electronic components.

Packaging made of antistatic fabric efficiently repels dust and is therefore the perfect choice for protecting parts during transport.

TIP: Browse through 6 ways how to use nonwovens for production facilities.

3. Hydrophilic Nonwovens

Regular nonwovens don’t absorb water well (especially when getting soaked for the first time). If you are looking for the opposite quality, hydrophilic nonwoven fabric is the answer.

Hydrophilic fabrics absorb water efficiently. Here’s the process behind the finishing which is done post-production: the fabric passes through a special “mist“ — this reduces the surface tension of the material and allows the water drops to soak into the fibres.

Hydrophilic nonwovens are utilised e.g. to make disposable mattress pads for surgeries.

4. Spunbond with Microfibres

These fabrics are made of much finer fibres than regular nonwovens are.

“Spunbonds with microfibres have a smooth surface; soft to the touch and not prone to getting scratched. They are often used for products that come into direct contact with human skin such as baby nappies, as well as with polished surfaces such as mirrors,“ adds Milan Polouček.

Spunbond with microfibres is quite a novelty as older machines were not able to produce such fine fibres.

They’re popular in the beauty industry — e.g. when a beautician applies a face mask on their customer and then covers it with a single-use nonwoven fabric for it to absorb better.

5. Flame-retardant Nonwovens

Flame retardants are added to nonwovens to delay flame ignition and prevent the spread of fire.

These fabrics are popular in the construction industry and fire prevention: if a fire breaks out in a building, the nonwoven fabric only melts — instead of going up in flames.

6. Customisation

Spunbond nonwoven fabrics can consist of more spunbond layers.

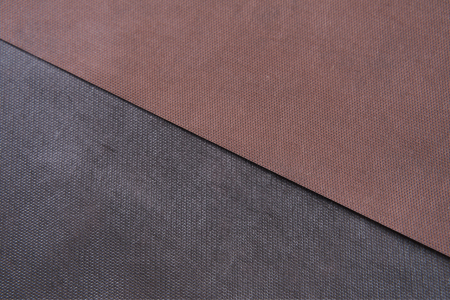

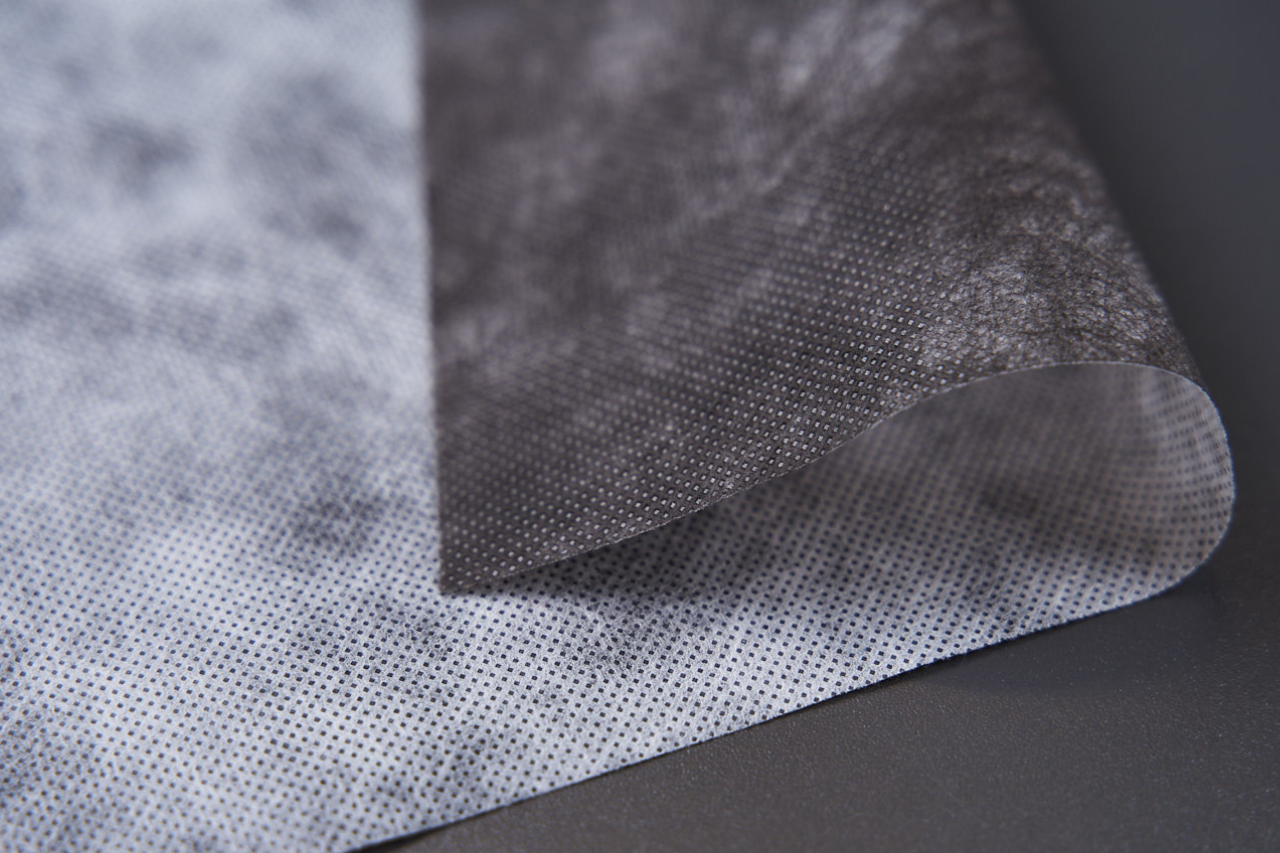

Composite spunbond fabrics are popular with gardeners. At Milmar, we supply hobby markets with textiles black on one side and brown on the other — and leave it up to gardeners to choose which colour they prefer on top.

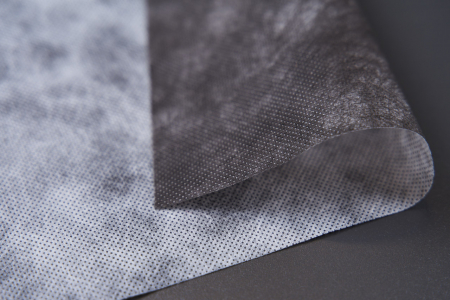

Two-colour composite spunbond fabric – black and brown.

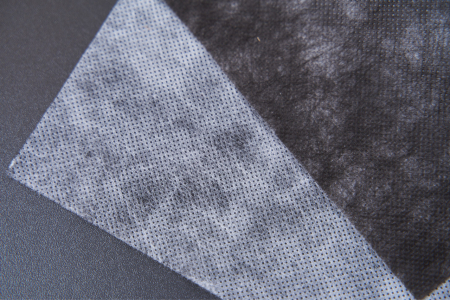

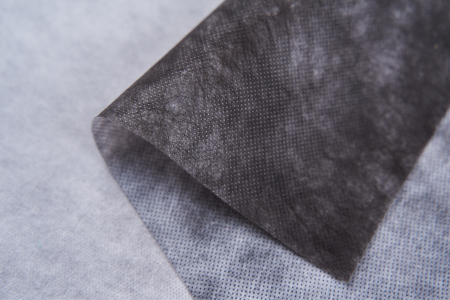

We also produce packages with black and white textiles. If gardeners want to warm up the soil, they turn the fabric the black side up — and if they wish to suppress the heat, they put the white side up.

Two-colour composite spunbond fabric – black and white.

We came up with the brown-black and black-white spunbond nonwoven about 10 years ago, driven by the needs of our customers. Combining the two colours into one fabric simply made sense. Another benefit is that the brown colour blends in nicely with mulch (black is too pronounced).

TIP: Read how to pick landscape fabric for mulching.

Nonwoven Produced in the Heart of Europe

At Milmar, we’ve been producing nonwovens for over 25 years and supply all the fabrics mentioned in this article. Are you looking for packaging? Cuttings for production? Nonwovens for your garden? Look no further.

We also take pride in sourcing materials only from trusted European suppliers to guarantee top-notch quality.

Get in touch, we’re happy to help.