Growing Strawberries In-Ground

Over 30,000 strawberry plants are grown in-ground at the Research and Breeding Institute of Pomology in Holovousy in the Czech Republic.

Let’s take a closer look.

At the Institute, they use nonwovens for growing strawberries for several reasons:

- The fabric works as a weed stopper — farmers don’t have to use herbicides as much. This reduces costs and is more eco-friendly.

- Without nonvowens, caring for strawberry plants is more demanding and requires more human labour.

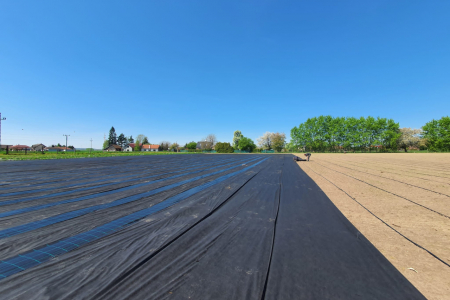

Growing strawberries with nonwovens at the Institute in Holovousy, the Czech Republic.

Planting Strawberries Using Nonwoven Fabric

1. Irrigation

Drip irrigation is placed on a prepared field. Strawberry plants receive all the moisture they need, and water doesn’t get wasted (as with other irrigation methods).

2. Laying Nonwovens

Workers unwind the nonwoven fabric from the roll manually. They run the centre of the strip over the irrigation and secure the fabric with metal pegs.

The Institute gets nonwoven fabric of these parameters from us:

- 45 g spunbond,

- in black colour,

- with UV stabilisation,

- in a 1,6 × 500 metre roll,

- with 30 × 30 cm square cut-outs for strawberry plants, spaced 30 cm apart.

3. Laying Woven Agrotextiles

Where the two strips of nonwoven fabric meet, workers lay down woven agrotextile (in narrow square strips as pictured) and secure it with metal pegs. Agrotextile fabric allows a small tractor to pass, protects nonwovens from mechanical damage, and prevents weeds from growing in the bed — this also reduces the use of herbicides.

4. Preparing Planting Cut-Outs

The nonwoven comes with perforation — cross-shaped holes in the fabric. The crosses are semi-finished as the fabric remains together in the middle. This prevents the perforation edges from bending and binding when the fabric is unrolled.

Before planting strawberries, the fabric in the middle of the cross-shaped hole is torn (simply by hand) to create a proper cut-out.

5. Frigo Strawberry Planting

At the Institute, they plant frigo strawberries into the holes — these chilled seedlings are very popular among farmers. They are cut from the crops from November until the end of January and offer multiple benefits such as overall strength and less need for irrigation.

For frigo strawberries, strawberry plants are treated with fungicides and stripped of leaves and soil — only the core stem and roots are left. These seedlings are stored in polythene bags at temperatures of 1 to 2 degrees Celsius and planted in the spring. With successive planting, the harvest season gets extended the first year.

Growing Strawberries on Mounds Using Nonwoven Fabric

Our customer Jan Blažek is a farmer who has been growing strawberries for over 20 years on his fields in Kbelnice in the northeast of the Czech Republic. For years, he used polyethene film for his strawberry fields (with machine-cut round holes).

However, the method had its cons – the sun-heated foil would burn the ripening strawberries and didn’t let water through. Cutting holes was another minus. The machine left cut-out circles on the film — and they had to be picked up by hand.

Eight years ago, Jan Blažek decided to switch to nonwoven fabric with pre-cut holes. Here’s what he appreciates the most:

- the fabric doesn’t overheat as much as foil — strawberries don’t get burned,

- nonwovens are water-permeable — there’s no need to water the plants if it rains,

- no need to collect cut-out circles (machine-made) manually — the fabric is perforated.

Jan Blažek plants strawberries in raised mounds — this method is also called the hill system. If it rains a lot, the water drains down from the mounds — the strawberries don’t get soaked and the risk of rotting is lowered. Plants get more sun exposure and ripen well. Easier harvest is another benefit; one does not have to bend over so much.

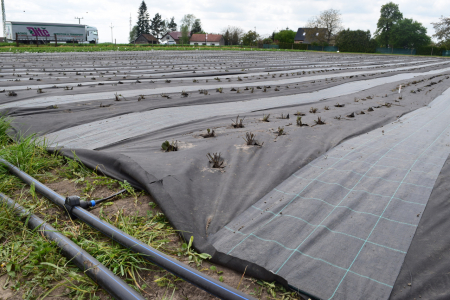

Mounds covered with a nonwoven fabric, ready for planting.

Planting Strawberries in Mounds Using Nonwoven Fabric

1. Preparing Mounds and Stretching the Irrigation

First and foremost, raised mounds are made in the field. The hose is laid on the top of the mound.

2. Laying of Nonwoven Fabric

Workers lay a strip of nonwoven fabric on each mound. Jan Blažek gets a nonwoven fabric with these parameters from us:

- spunbond 60 g,

- in black colour,

- with UV stabilisation,

- in a 1.15 × 500 metres roll,

- with cut-outs in a row, 20 cm apart.

3. Opening Up the Holes

The prepared cross-shaped holes in the nonwoven fabric get torn to create a proper hole.

4. Planting Strawberries

Jan Blažek plants frigo strawberries – here’s what older strawberry plants look like on the mounds. The oldest plants are three years old.

Want a Nonwoven Fabric for Your Strawberry Fields?

You have come to the right place. At Milmar, we supply farmers with rolls of black nonwovens for strawberry fields. Choose your preferred parameters:

- the strip width,

- the fabric weight,

- placement of the cut-outs for the strawberry plants.

Get in touch with us today!