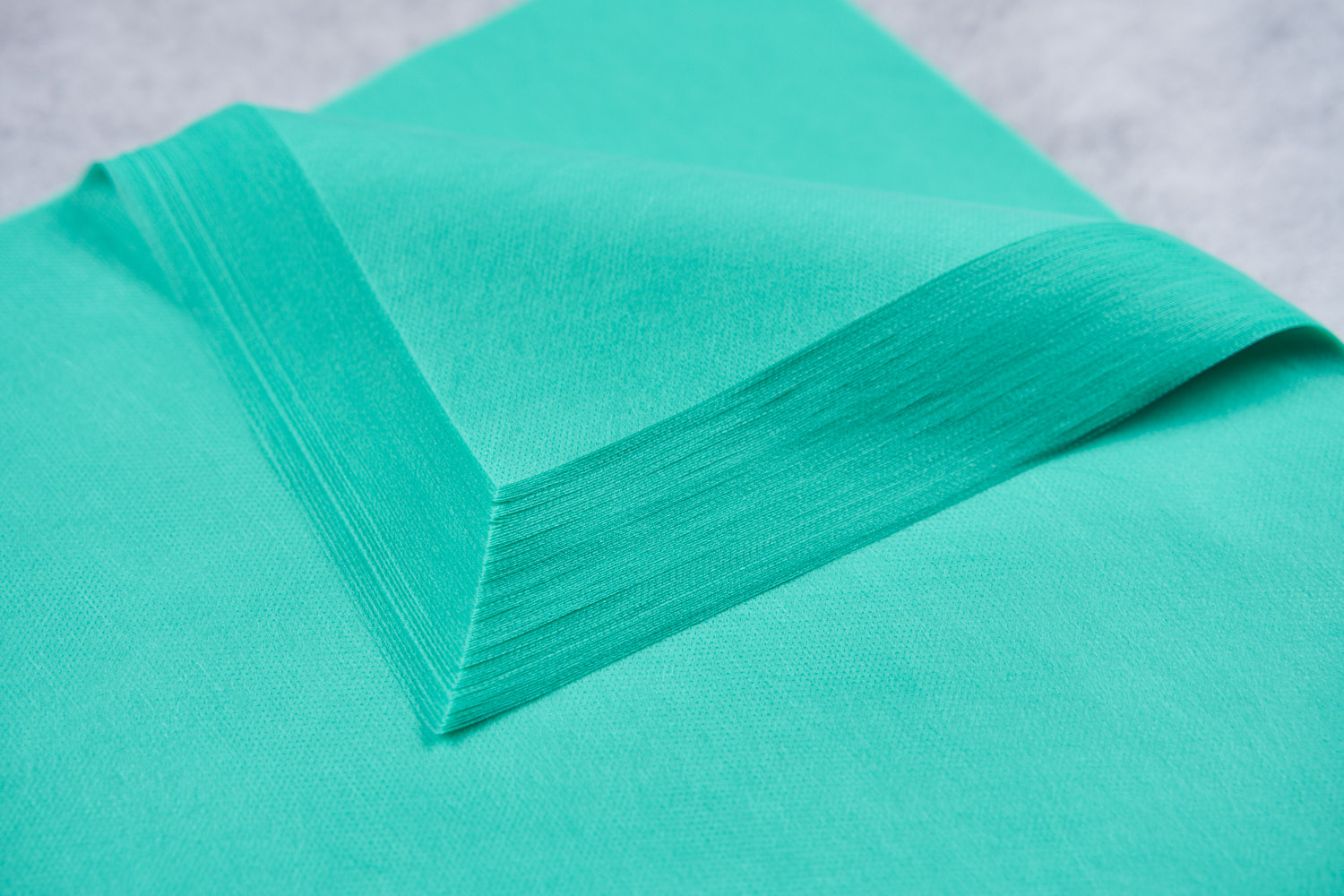

The Spunbond Manufacturing Method

Spunbond nonwovens are made on a specialised spunbond line (spunbond machine).

Spunbond machine from Suntech Textile Machinery.

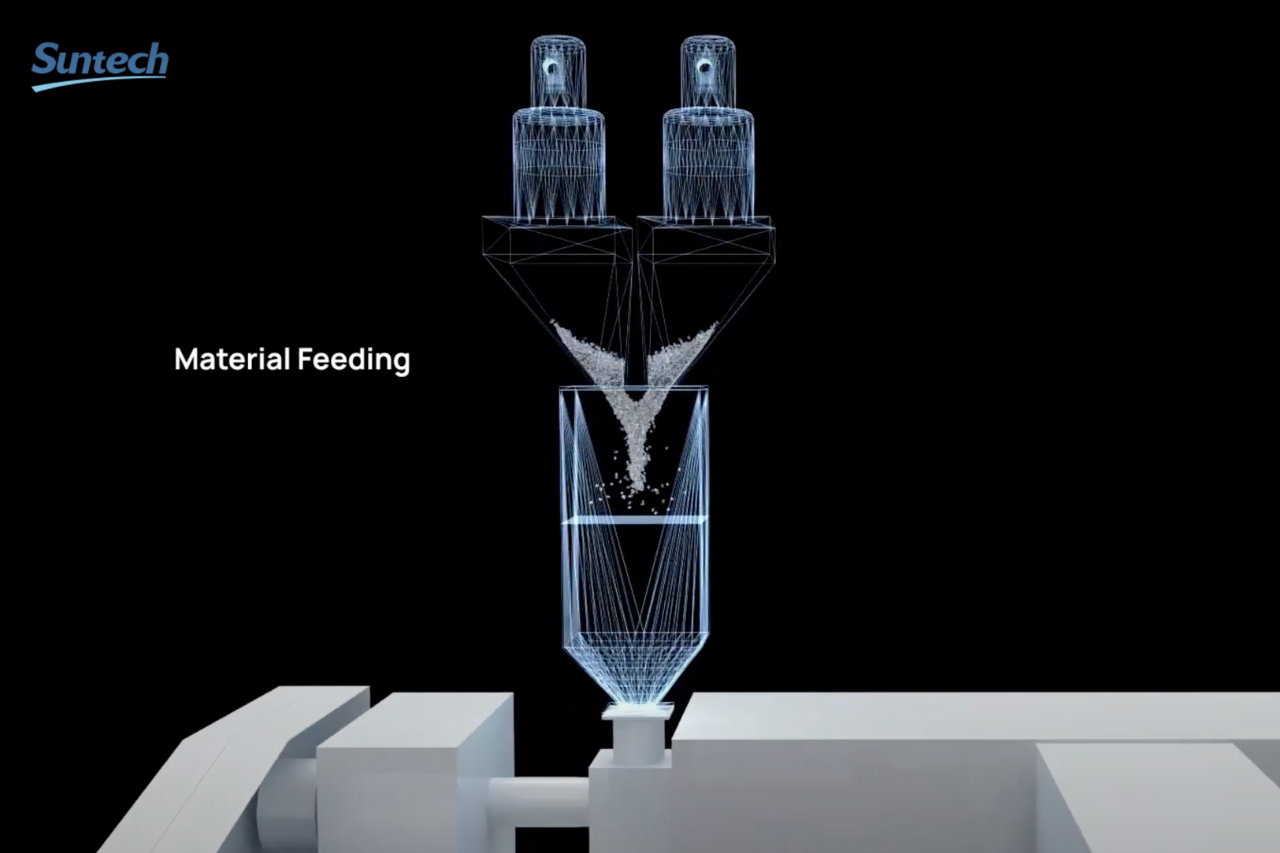

Nonwovens are made of polymer (usually polypropylene) granules.

Polypropylene granules feeding into a spunbond machine. Source: Suntech Textile Machinery.

Starting in the feeding tubes of a spunbond machine, granules continue to the extrusion tube where they get mixed with colouring agents, stabilisers, and other additives.

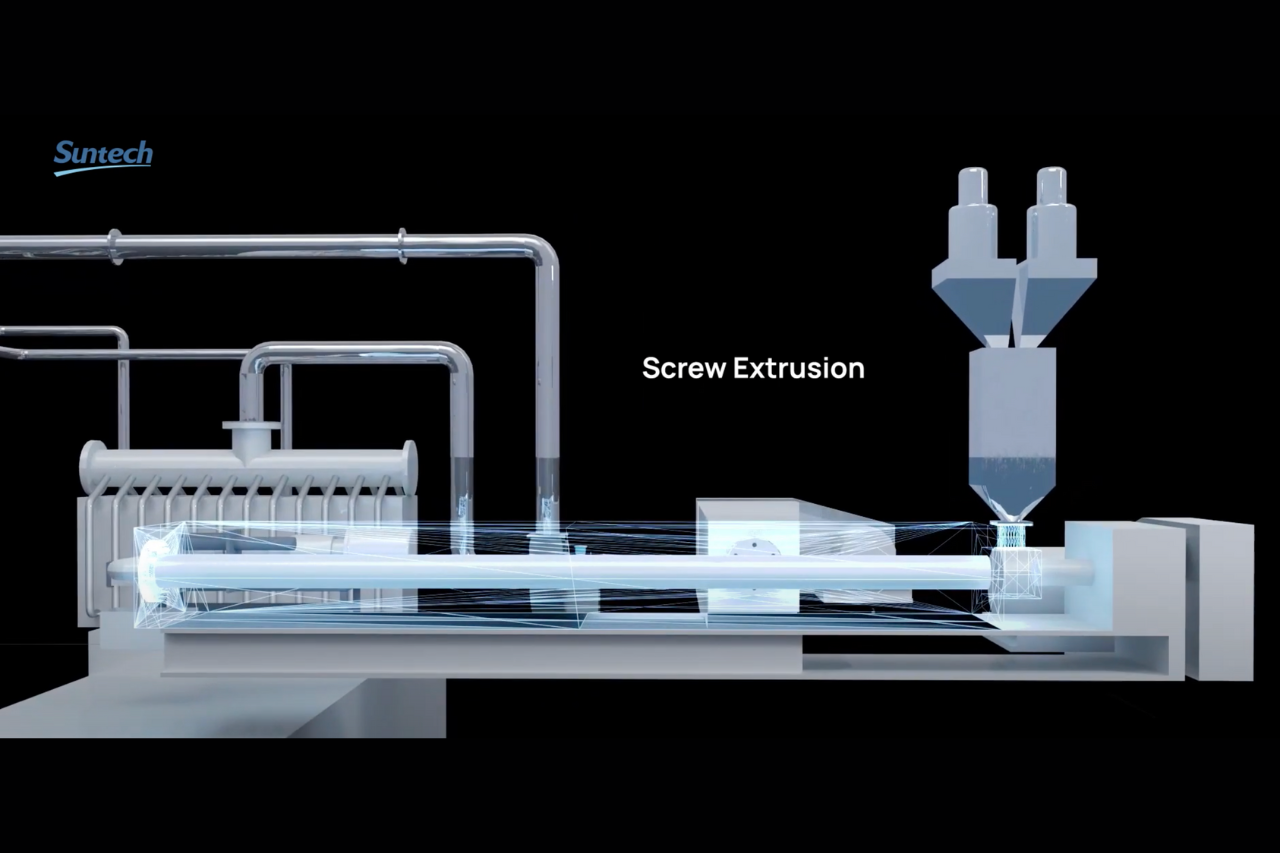

The extrusion tube. Source: Suntech Textile Machinery.

As the next step, the polypropylene mixture gets melted, while still in the extrusion tube.

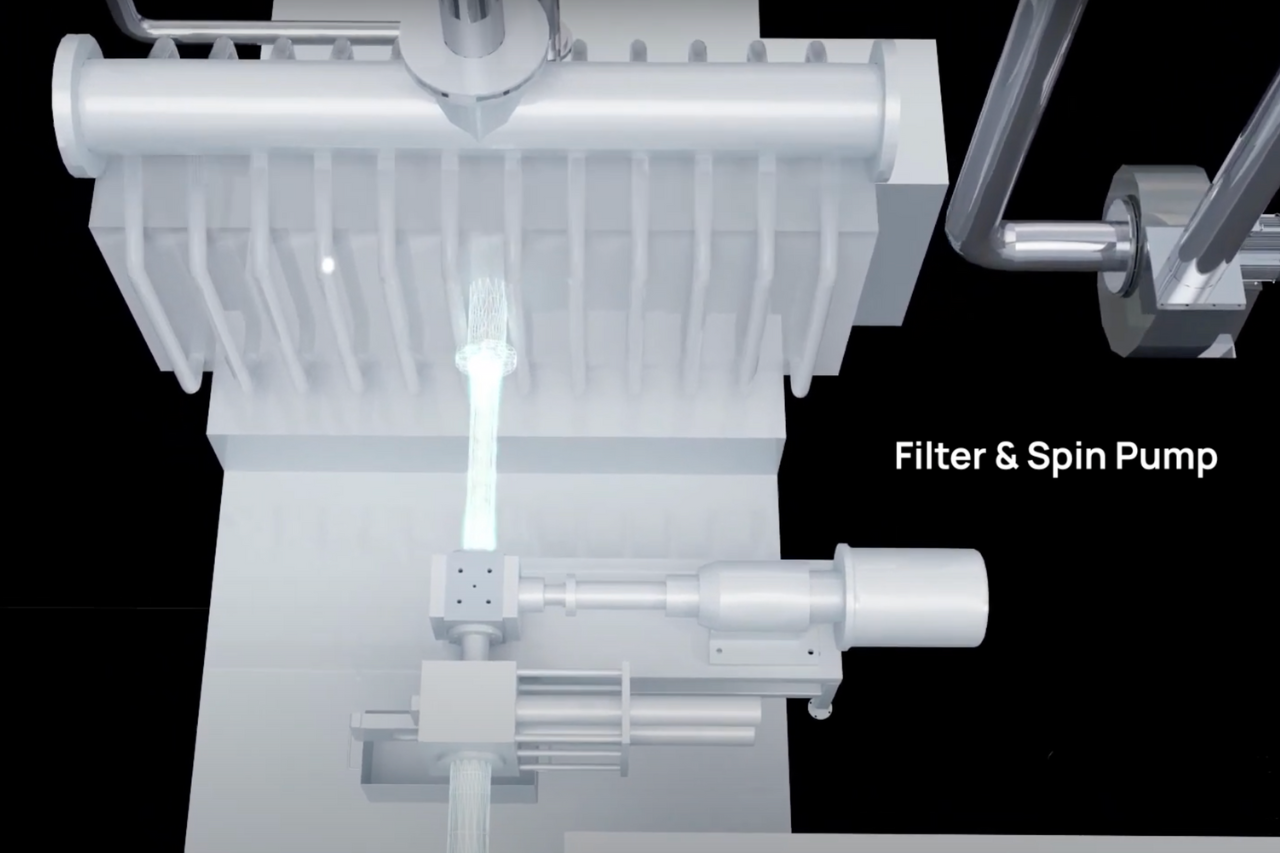

Filter and spin pump of a spunbond machine. Source: Suntech Textile Machinery.

The melted mass is pushed through a filter, separating polypropylene particles from additives. Then it’s pumped to the spinning box.

A spinning jet transforms liquid polymer into thousands of delicate fibres. Source: Suntech Textile Machinery.

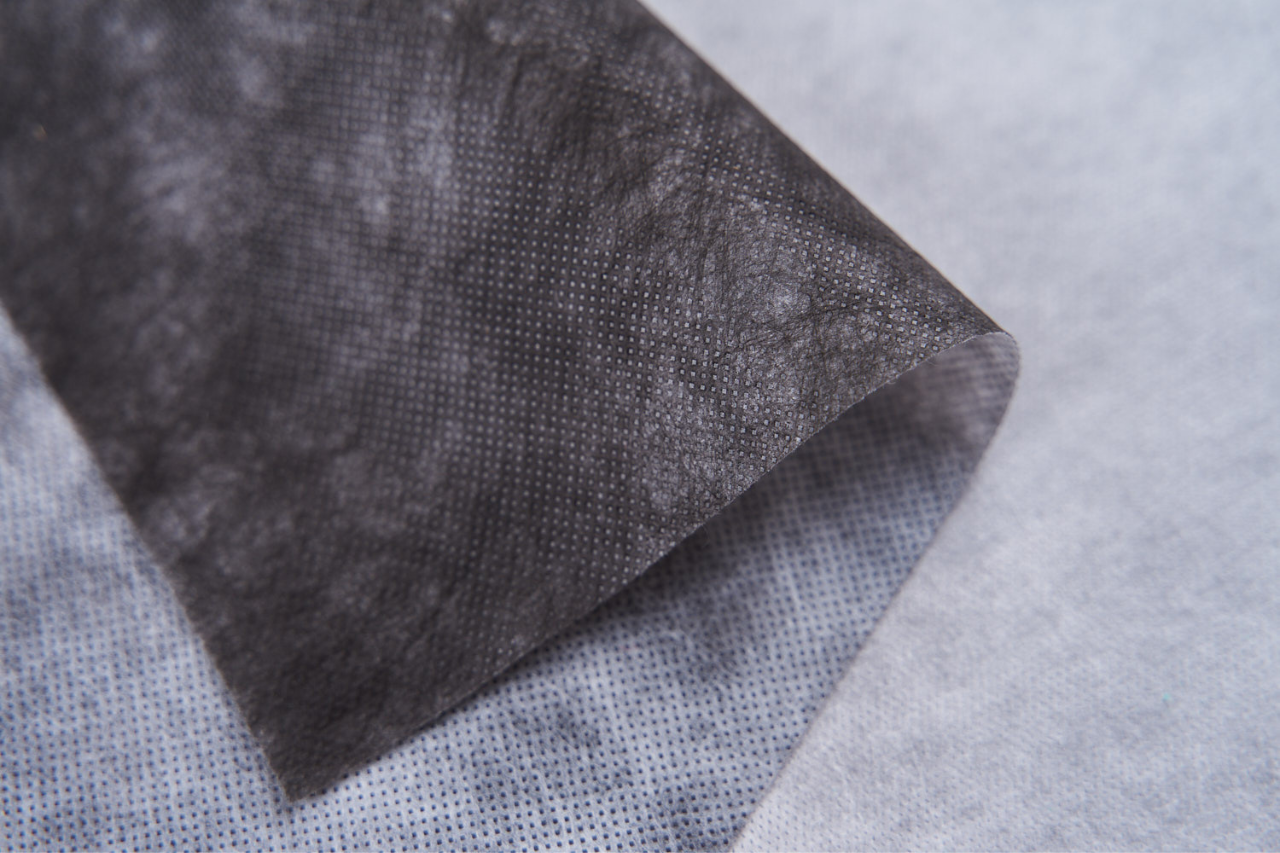

A spinning jet forms fibres of 10–30 micrometres in diameter. The formed fibres either cool down on their own or get dried in the forming system. The latter technique improves mechanical qualities of the fibres — they extend in length and get thinner when subjected to powerful air flow.

Dried fibres are transported to a net forming zone on a conveyor belt. Nonwovens can be formed:

- by heat,

- chemically,

- mechanically.

Fibre-forming by heat is the most common. A layer of fibres goes into a section of the spunbond machine called the calander. Heated rolls in the calendar make them adhere to one another; forming a coherent layer of fibres.

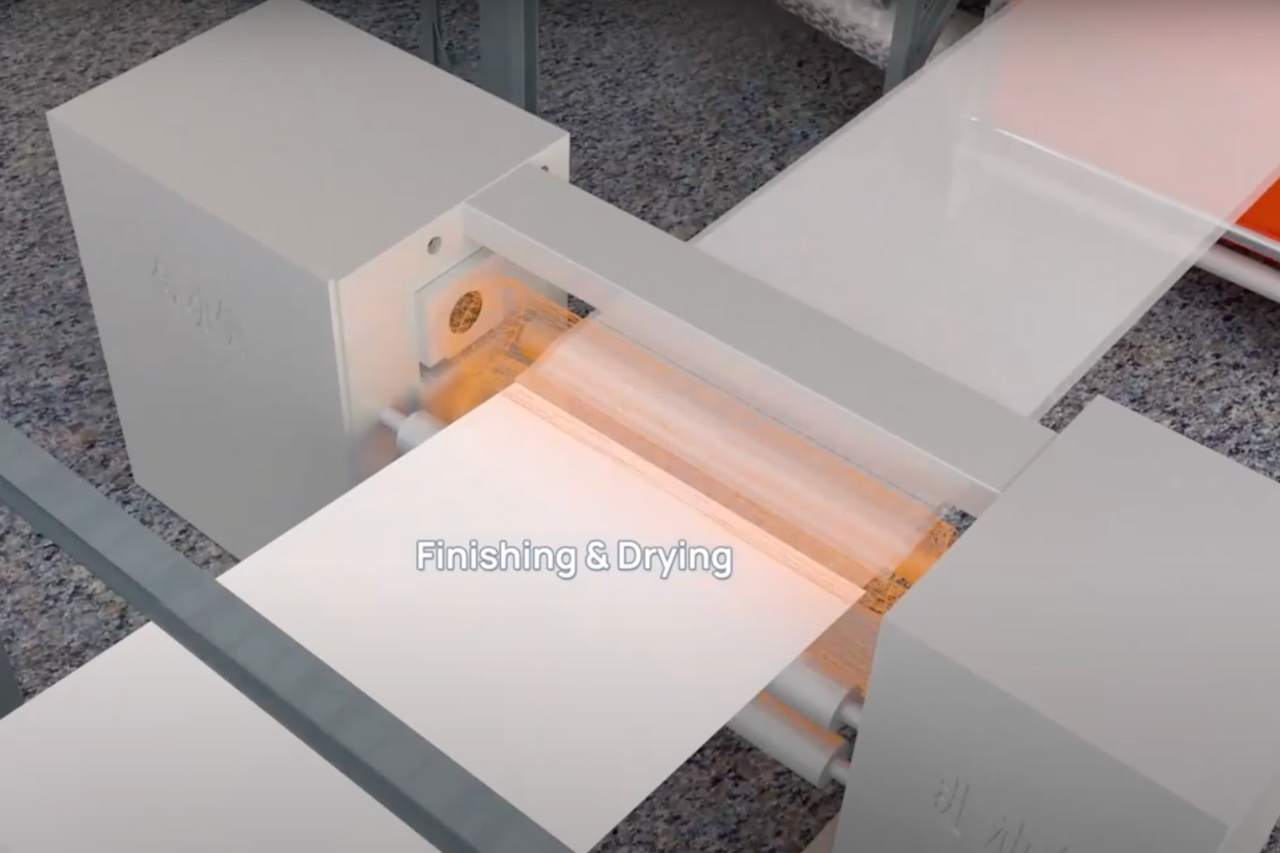

Finished nonwoven fabric coming out of a calander. Source: Suntech Textile Machinery.

One of the calander rolls might have a customised surface.

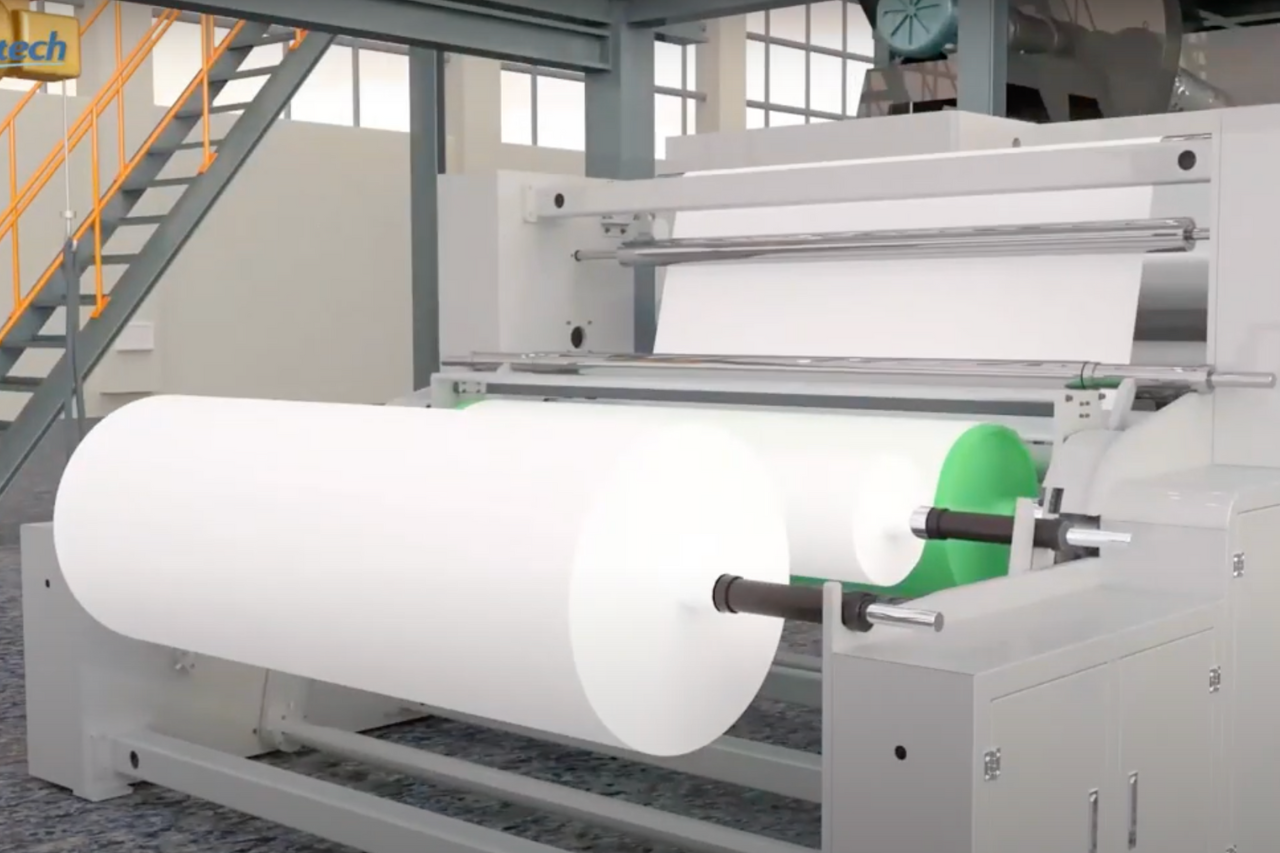

At the last step, finished spunbond nonwoven fabric is rolled up and stacked. Sometimes, it’s processed further (it may undergo antistatic treatment, for example).

Rolling it up. Source: Suntech Textile Machinery.

Spunbond Machine in Motion

Get a better outlook on the manufacturing process in this video of the spunbond machine:

The Meltblown Method

The second most common technology in nonwoven manufacturing is the meltblown method. The major difference between the spunbond and the meltblown method is the use of air. The spunbond method uses up less air and doesn’t require it to be hot.

When employing the meltdown method, the air temperature needs to be the same as the temperature of the melted polymer (or even higher). This method requires more air flowing at much higher speed and consumes more energy overall. Meltblown nonwovens are thus more expensive than spunbond nonwovens.

How We Make Nonwoven Products in Milmar

We mostly use spunbond nonwovens supplied by trusted European producers in our production.

We process spunbond nonwovens per request to meet our clients’ needs and requirements. We cut, weld, perforate, and print nonwoven fabrics on demand. Read detailed info to learn about customisation processes and have a look at the technical data sheet for spunbond nonwovens.

Do not hesitate to contact us to get more information on spunbond nonwovens or a price quote.