We have 20+ years of experience with manufacturing products made of nonwoven fabrics, which are manufactured by the spunbond method. We produce our custom-made products using only high-quality non-wovens supplied by verified European producers.

Application

The variability of spunbond nonwoven fabrics is unlimited — they can be utilised in various industries in countless different ways. Spunbond nonwovens are mostly used for protection, filtration, or decorative purposes.

Our customers use nonwovens:

- as protective packaging in the automotive industry,

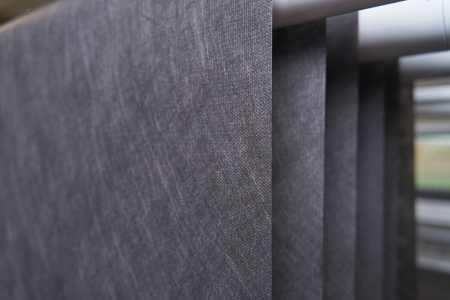

- to hold cushions and other types of padding in upholstery,

- as fabrics for strawberry fields,

- for component transport bags in mechanical engineering,

- for face masks and protective pads in healthcare,

- as weed barriers in gardening.

Wondering whether you could use spunbond nonwovens in your industry? Get in touch - we’d be happy to help!

How We Work

Our goal is for our spunbond nonwovens to meet our customers’ needs. We always discuss the customer’s situation and specifics first and manufacture products that suit the customer perfectly.

Per request, we customise our spunbond nonwovens mostly with:

- UV stabilisation,

- anti-static treatment,

- anti-scratch treatment,

- hydrophilic treatment (liquid absorption).

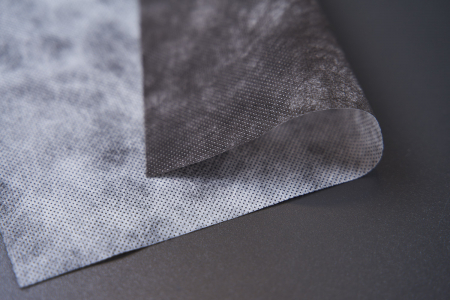

Material

Spunbond nonwoven fabrics are made of 100% polypropylene.

Spunbond nonwovens are manufactured on an extrusion line that melts and extrudes the polymer, creating fine filament yarn (with approx. 15–35 micrometres in diameter).

Next, the production line thins out the yarn, forms a web from the yarns on a conveyor belt and then binds them into a nonwoven fabric.

Some of the many pros of spunbond nonwovens are:

- they’re solid and resistant to wear and tear or other mechanical damage,

- air permeability (can be used to cover hot objects),

- water permeability (favourite feature in gardening),

- high yarn density (most types of weed won’t grow through).

We take pride in choosing only high-quality fabrics from verified European suppliers to make our products.

Manufacturing Methods

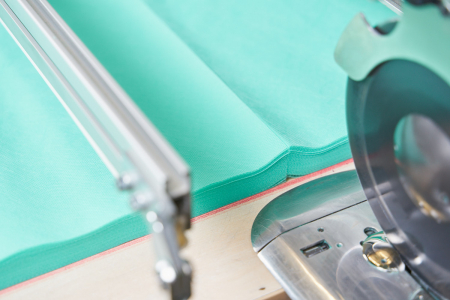

We use various techniques to manufacture spunbond products:

- Large-scale cutting is performed on an automatic production line.

- Products for small-scale orders are cut manually on a spreading table.

- We prepare long strip cuts on an automatic winding machine.

- We rewind fabrics from large rolls to smaller ones which can be cut to various widths.

- We also employ technology for continuous folding of sheet materials—thus reducing the width of the fabric by half.

- We prepare the material on a folding machine that reduces the width of the fabric by half.

- Then, we weld the prepared fabrics by using pulse welding technology and at the same time we separate the final products.

- The outputs are bags of various sizes including bags with a flap.

- We also employ punching technology of nonwoven fabrics.

- It is used when planting plants, especially strawberries and lettuce.

- Printing is performed on the principle of flexographic printing.

- We print simple monochrome descriptions, for example date or logo.

Documents to Download

| Specifications Overview | Declaration of Conformity |

|---|---|

| DOWNLOAD | DOWNLOAD |

| Data Sheet - 16g | Data Sheet - 17g | Data Sheet - 19g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 23g | Data Sheet - 30g | Data Sheet - 35g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 40g | Data Sheet - 45g | Data Sheet - 50g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 60g | Data Sheet - 70g | Data Sheet - 80g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 90g | Data Sheet - 100g | Data Sheet - 110g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 120g | Data Sheet - 130g | Data Sheet - 140g |

|---|---|---|

| DOWNLOAD | DOWNLOAD | DOWNLOAD |

| Data Sheet - 150g |

|---|

| DOWNLOAD |

Get in touch and we'll get started!

Interested in spunbond nonwoven fabrics? Let us know! We'll be happy to discuss your needs and find the best solution for you.

You may also be interested