Using plastic mesh protective packaging always pays off. It’s inexpensive — one piece costs literally a few cents, and it provides effective protective padding to products which are usually worth much more.

In most cases, typically in heavy industry, protective packaging is used when parts are being supplied to production facilities (such as headlights in the automotive industry). That said, plastic netting is also used as protective packaging for the final product. You often come across it in the food industry — think multipacks of garlic or Babybel cheese.

At Milmar, we specialise in both protective packaging for individual products as well as separation liners for grouped packaging. In this article, we describe the possibilities of plastic mesh and plastic netting, and give you advice on choosing the best type of protective packaging for your production.

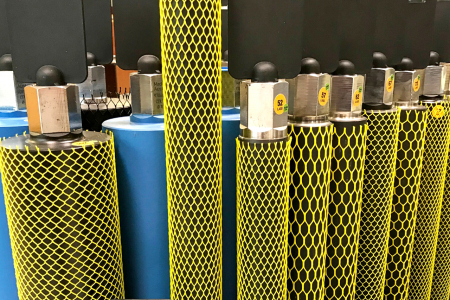

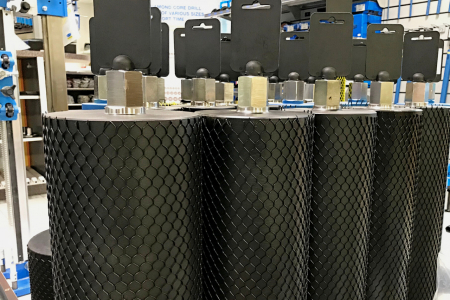

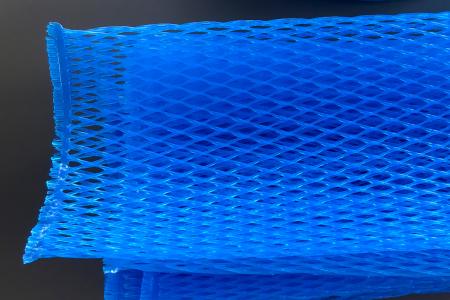

1. Protective Plastic Mesh Sleeve

Protective sleeve is either open on both ends, or one of its ends is sealed. The latter type is perfect when you need to prevent the product from slipping out of the protective sleeve.

Plastic netting protects the legs of chairs during transport.

When choosing plastic mesh protective sleeves, pay attention to these parameters:

Sleeve Diameter

Diameters of plastic mesh protective sleeves usually range from 1 to 80 cm. Plastic mesh is elastic — which means the ideal diameter should be slightly smaller than the product you put inside. When wrapping a product of varying thickness, try out a few protective sleeves of various diameters before sending in a bulk order (we’re happy to provide samples beforehand, ask us for them anytime).

Thread Weight

The weight of individual threads affects the elasticity/firmness of the plastic netting. Remember: threads should be soft enough to cling tightly to the product, but also strong enough to not tear when putting the product in. Not sure which thread weight to choose? Reach out to us — we’ll recommend the most suitable one.

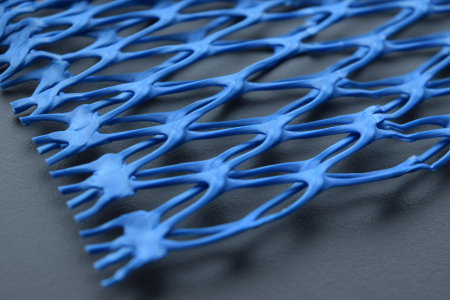

Mesh Size

The golden rule is: the smaller the product inserted in the protective sleeve, the smaller the mesh size (mesh size = size of holes in the netting).

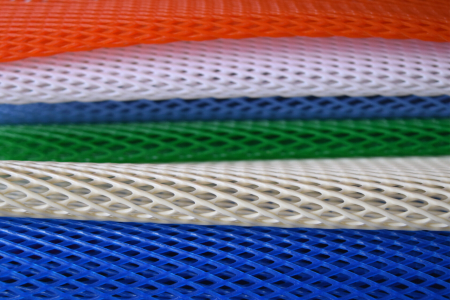

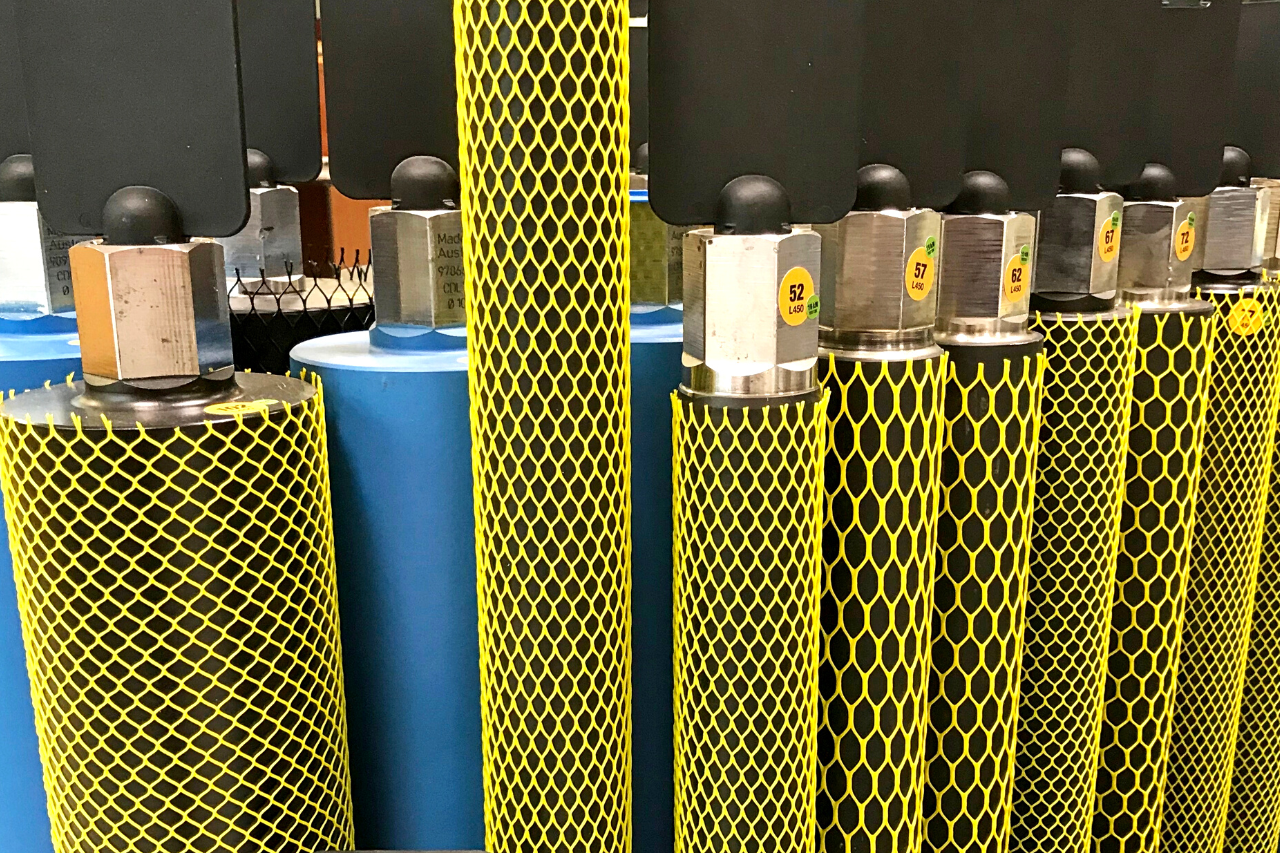

Colour

To make various diameters of plastic netting easily distinctable, we assign each diameter of plastic netting its colour — so that you can tell them apart even from a distance. The colours are 100% customisable — if you choose a diameter but don’t like its default colour, we change the colouration to suit your needs.

Protective mesh sleeve nets are a colourful bunch.

Plastic Netting Spreadsheet

Choose protective sleeves quickly and correctly: here’s a helpful table with all the parameters you should consider when shopping for plastic mesh protective packaging. Including recommended diameter of the inserted product, colour of the netting, mesh size, and even technical data sheets for download.

More Tips for Mesh Protective Sleeves

Putting a protective mesh sleeve on a long and slender product may turn out to be a bit tricky due to friction. In such cases, we recommend cutting the protective sleeve into shorter parts, then rolling them up one by one.

Oftentimes, the product doesn’t need to be covered with the protective sleeve in all its length. Three shorter sleeves work just as well: two sleeves on each side and one sleeve in the middle. This way you can pile products on top of each other in grouped packaging without them actually touching each other.

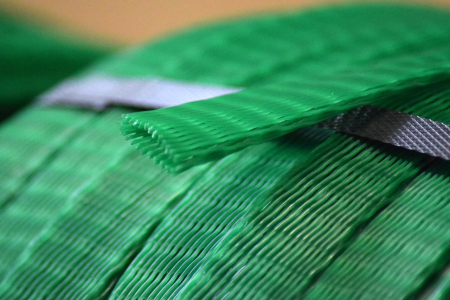

2. Mesh Separation Liners

Plastic mesh cut in squares or rectangles makes perfect separation liners for grouped packaging. These are used when there’s a risk of products scratching or otherwise damaging each other. Firm plastic netting is usually your best choice for separation liners.

At Milmar, we either supply plastic netting cut into required shapes and sizes, or send you an entire roll and you cut your own liners out of it. Whatever suits you better.

Upon request, we manufacture separation liners in various colours. For example, a client of ours uses blue liners for packaging in Czechia and orange ones for packaging that gets sent out to Germany. The employees in both countries are able to tell at just a glance to which facility the packaging belongs. It’s as simple as that.

For some clients, we provide plastic mesh protective sleeves with EVA finish which is similar to rubber finish. Its benefit is that it’s not slippery — which makes it the best choice for metal parts.

Here’s more on separation liners:

Picking Perfect Packaging: Nonwoven Fabric vs. Plastic Mesh?

Apart from plastic netting, industries also use nonwoven fabric as protective packaging. Not sure which one of the two materials to choose? It depends mostly on the product and what you need to protect it from.

If protection against dust is your top priority, choose a nonwoven fabric with anti-static treatment — very popular for delicate electronics, highly susceptible to damage by dust.

OUR TIP: Here’s more on the topic of nonwovens as packaging.

For long and slender products which are not so susceptible to dust, we recommend choosing plastic mesh protective packaging.

Made-to-Measure Plastic Mesh

Looking for mesh protective packaging or mesh separation liners? Get in touch — we will be glad to recommend the best one for your purposes.

When shopping for protective sleeves, let us know the diameter of your products and we’ll send you various samples to try them out.