At Milmar, we make high-quality products from nonwoven and woven fabrics and plastic netting — mostly for Home & Garden, such as nonwovens for strawberry fields or covers protecting plants against ground frosts. Our nonwovens are also used in industrial production.

We don’t sell our products directly to gardeners but supply them to distributors. Our nonwovens and plastic mesh are often custom-made, and we always need to know their required dimensions and packaging to pack and label them correctly.

In the best-case scenario, our clients would tell us months in advance how many products they need for the upcoming spring season, so that we could stock up. That said, it is difficult for distributors to predict whether demand will stay the same as in the previous year, decrease or increase.

We have been in the business for over 20 years and have learned to be flexible. These 4 steps help us manage the unpredictable seasonal demand:

1. Stocking Up

We always keep high stocks of material. This saved us even during the COVID-19 pandemic; back then, supply chains had broken down, resulting in numerous companies lacking material and being unable to produce. That didn’t happen to us — our stock of spunbond helped us get through the pandemic. Since then, we have always done our best to keep our stock high.

2. Production to Stock

In autumn and winter, we produce and stock up in advance to get ourselves ready for the season. That said, we always need to consider carefully how high our stock should be. When we produce too much, uncollected products block our warehouse and we waste costs.

3. Increase in Production

Here’s a common scenario: it’s early spring, a period of lighter frosts hits, and anti-frost nonwovens sell out quickly in shops. When this happens, our phones start ringing and clients start ordering more products.

If we don’t have the product for which there’s an increased demand in stock, we must act quickly — delivering 3 weeks later makes absolutely no sense as frosts would be over and no one would need the products anymore.

To accommodate our clients’ needs, we reschedule the production. If necessary, our employees work overtime temporarily. We may even introduce a second (or third) shift for the time being, or work Saturdays. And our part-time workers step in.

4. Repackaging of Products

Certain products differ in packaging. Sometimes it makes more sense to repackage the products (that are in a different packaging already) — so we don’t have to change the current production schedule. It’s more efficient that way.

Flexibility Is Key

Large companies have their production scheduled for weeks in advance, and their processes don't allow for quick changes. At Milmar, it's different.

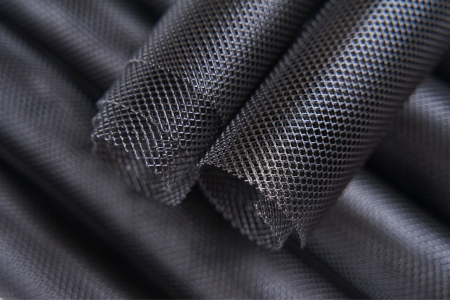

Our production facility for nonwovens and plastic netting in Czechia.

Anytime you order more seasonal products, we are usually able to quickly rearrange our production while still managing other orders and meeting all our deadlines. We think through the best way to accommodate your needs and get back to you within an hour with details.

That’s one of the reasons why our clients have stayed with us for more than 20 years. Based on what they say, our competitors contact them occasionally, offering a lower price for a few products from their portfolio. Yet the clients are not interested.

It‘s not about saving a few pennies but about finding a reliable and flexible supplier. When you sell out during the season and your inexperienced supplier cannot produce immediately, you can lose profit as well as some customers. The big players aim to make profit long-term, and we’re glad to be their reliable partner.

If you're looking for a supplier of nonwovens and mesh products, feel free to get in touch!